14/07/2025

2 دقيقة قراءة

التوائم الرقمية: كيف يمكن لإنشاء نسخة افتراضية من عملياتك أن يوفر لك الوقت والمال

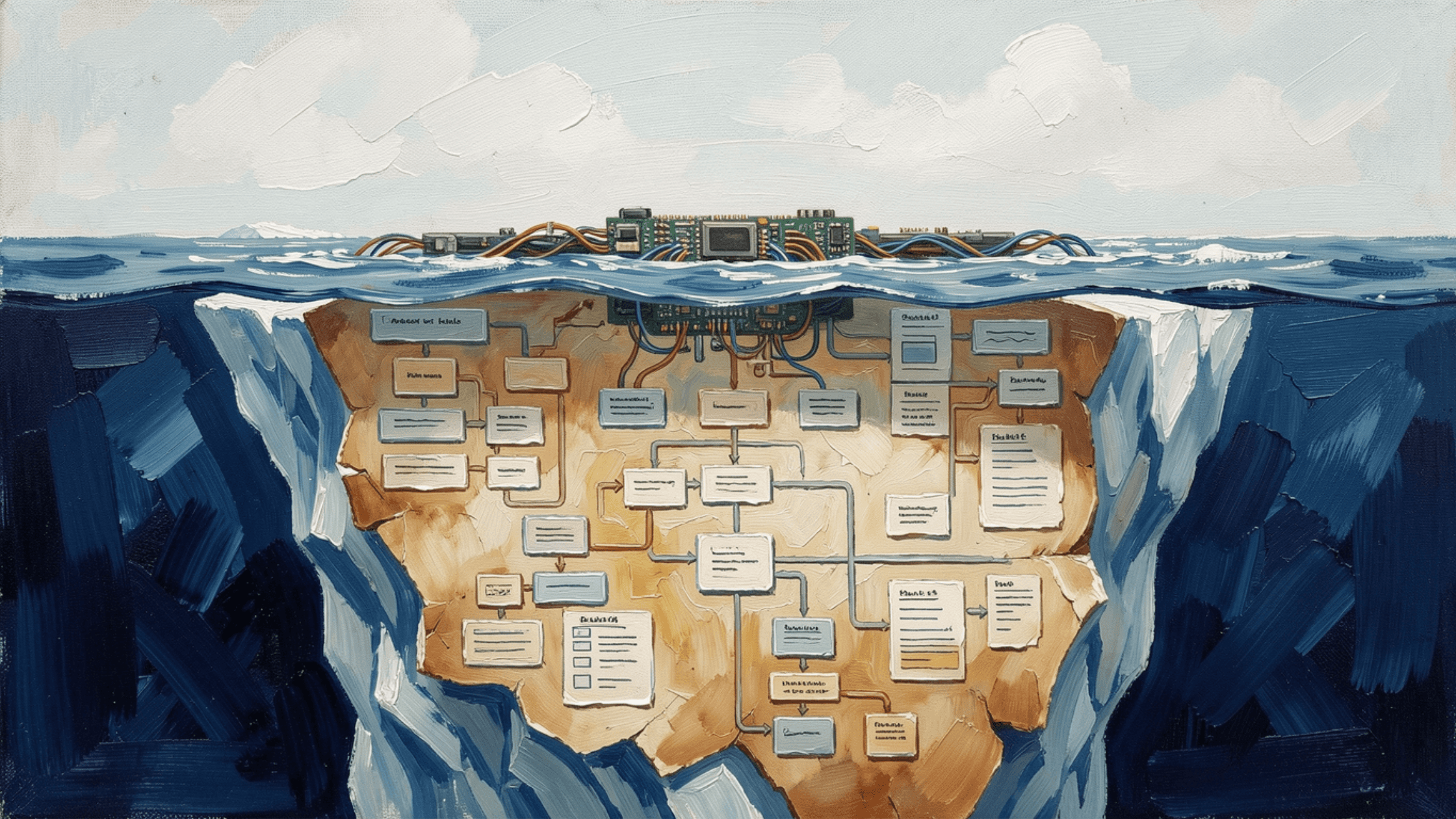

في عالم الأعمال المتزايد التعقيد وسريع الوتيرة، تواجه الشركات ضغوطًا مستمرة لتخفيض التكاليف، وتحسين سير العمل وزيادة المرونة. واحدة من أقوى الابتكارات التي تلبي هذا الاحتياج هي التوأم الرقمي — نسخة افتراضية من نظام أو عملية أو أصل مادي. هذه النماذج المعقدة تحاكي العمليات الواقعية في الوقت الفعلي وأصبحت حجر الزاوية في استراتيجيات التحول الرقمي.

لرواد الأعمال الذين يهدفون إلى تبسيط أعمالهم، توفر التوائم الرقمية — خاصة عند اقترانها مع وكلاء الذكاء الاصطناعي والأتمتة الوكيلية — حلاً قابلًا للتطور وذكيًا وفعالًا من حيث التكلفة لتعزيز الكفاءة ودقة اتخاذ القرارات.

أهم الأفكار

تمكن التوائم الرقمية من تحسين العمليات التجارية المعقدة في الوقت الفعلي.

يتم دمجها مع وكلاء الذكاء الاصطناعي، حيث تقوم بأتمتة القرارات وتقليل الوقت والتكلفة.

قابلة للتطبيق عبر الصناعات – من التصنيع واللوجستيات إلى البيع بالتجزئة.

التعريف والمعنى: ما هو التوأم الرقمي؟

التوأم الرقمي ليس مجرد نموذج ثلاثي الأبعاد أو محاكاة. إنه تمثيل رقمي حي مدفوع بالبيانات لعملياتك المادية، يتم تحديثه باستمرار بواسطة البيانات في الوقت الفعلي عبر أجهزة الاستشعار أو واجهات برمجة التطبيقات أو الأنظمة المتصلة. هذا يخلق حلقة تغذية مرتدة بين البيئات المادية والرقمية، مما يمكنك من الحصول على رؤى متقدمة وتنبؤات وأتمتة.

عند تضمينه في منصة وكيلية، يتطور التوأم الرقمي إلى ما هو أبعد من أدوات المراقبة السلبية. حيث يصبح أنظمة ديناميكية تتطور بنفسها، خاصة عند دمجه مع وكلاء الذكاء الاصطناعي القادرين على المراقبة والتعلم والتصرف بناءً على البيانات.

كيف توفر التوائم الرقمية الوقت والمال

تقدم التوائم الرقمية مزايا قابلة للقياس من خلال عدم تمثيل العمليات فحسب، بل تحسينها بنشاط. عند دمجها مع وكلاء الذكاء الاصطناعي، تصبح أدوات قوية لجعل العمليات أكثر ذكاءً وسرعة وكفاءة من حيث التكلفة.

تشمل الفوائد الرئيسية:

تسريع اتخاذ القرار: يتيح المراقبة في الوقت الفعلي تحديد الكفاءات بسرعة ومحاكاة التغييرات التشغيلية قبل تنفيذها.

أتمتة العمليات المتكررة: يمكن للوكلاء الذكاء الاصطناعي المدمجين أن يتصرفون بشكل تلقائي على الإدخالات البياناتية، مما يقلل من الحاجة إلى التدخل اليدوي.

الصيانة التنبؤية: يكتشف التحليل المستمر للبيانات العلامات المبكرة للأعطال، مما يجنب التعطل المكلف ويمد دورات حياة المعدات.

التدريب بدون تعطيل: يمكن للموظفين التفاعل مع النماذج الافتراضية لتعلم الإجراءات أو اختبار السيناريوهات دون التأثير على العمليات الحية.

الاستخدام الأمثل للموارد: تساعد المحاكاة في تحسين استهلاك الطاقة، واستخدام المواد وتدفقات سلاسل التوريد.

التجريب بدون مخاطر: إجراء اختبارات استراتيجية لنماذج الأعمال الجديدة، أو تصميمات التخطيط أو تحسين العمليات دون المخاطرة المالية.

التخطيط الاستثماري المبني على البيانات: توفر السيناريوهات المدعومة بالبيانات الثقة في قرارات تخصيص رأس المال.

تقليل الهدر التشغيلي: التعديلات في الوقت الفعلي تمنع الإنتاج الزائد، أو الوقت الضائع أو فائض المخزون.

عند مزجها مع سير العمل الوكيلي، لا يخبرك التوأم الرقمي بما هو خاطئ فقط — بل ينفذ الإصلاحات بشكل تلقائي أو يطلق الاستجابات المحددة مسبقًا من خلال الأتمتة الوكيلية.

أمثلة على التطبيقات عبر الصناعات

لم تعد التوأمة الرقمية مقتصرة على العمالقة الصناعيين — بل أصبحت حلاً عمليًا للشركات المتقدمة في كل قطاع تقريبًا.

التصنيع:

المراقبة الفورية لمقاييس الإنتاج

تحديد اختناقات العمليات

محاكاة تغييرات التوزيع دون توقف العمليات

الخدمات اللوجستية:

نسخ رقمية لسلاسل التوريد لتوقع تغييرات الطلب

تحسين مسارات التسليم

محاكاة الانقطاعات مثل إغلاق الموانئ أو نقص المواد

التجزئة:

نماذج متاجر افتراضية لاختبار توزيع المنتجات وأنماط حركة المرور

تجريب تخطيطات موسمية بناءً على البيانات

تحسين تجربة العملاء وزيادة المبيعات

الطب:

محاكاة تفاعلات الأدوية والتنبؤ بالآثار الجانبية

تجارب سريرية افتراضية لتقليل المخاطر

تحليل بيانات الدراسة تلقائيًا

الطاقة:

إدارة أعباء البنية التحتية

نمذجة استخدام الطاقة

تكامل فعال لمصادر الطاقة المتجددة

تؤكد هذه الأمثلة على أهمية التوأمة الرقمية عبر الصناعات، خاصة عند تعزيزها بأتمتة الذكاء الاصطناعي وطبقات التكامل الذكية.

ميزة Beam AI

في Beam AI، نُمكّن الشركات من بناء وطرح وكلاء الذكاء الاصطناعي الذين يتفاعلون مع التوأم الرقمي ويستخرجون رؤى قابلة للتنفيذ ويبدؤون العمليات بشكل مستقل. منصتنا الوكيلة مصممة للمرونة والسرعة والاندماج على نطاق المؤسسات — سواء كنت تحاكي شبكة لوجستية كاملة أو تحسن خط إنتاج.